Protective Packaging Manufacturers

Are you looking for Protective Packaging Manufacturers in the UK? We offer a complete design and vacuum forming service to protect packaged goods.

At Plastics by Design we design, develop and produce all our protective packaging with the highest standards, delivering the best quality packaging to our customers.

We have a comprehensive customer service to target the best price, design, unique solutions, product loading and transportation for every client's project.

Vacuum Formed Protective Packaging

The safety of the product during transportation is the most significant aspect of protective packaging. We specialise in using the best possible vehicle test machine for our bespoke vacuum-formed plastic protective packaging.

Our professionals in the field ensure each product is given a drop-test on multiple surfaces to comply with all legal requirements and specifications.

The drop-tests we do are to keep all products and items safe from potential transportation damage.

Depending on the vehicle they are travelling in or the number of deliveries they are transported with, it is possible your company products, like electronics, tooling and foods, may get dropped or battered about during the journey.

With our professional team of qualified designers, we are aware of how to design and produce efficient packaging that enhances the stability of your products so that you can guarantee no matter what happens to your packages, the items inside will stay intact or not be distorted.

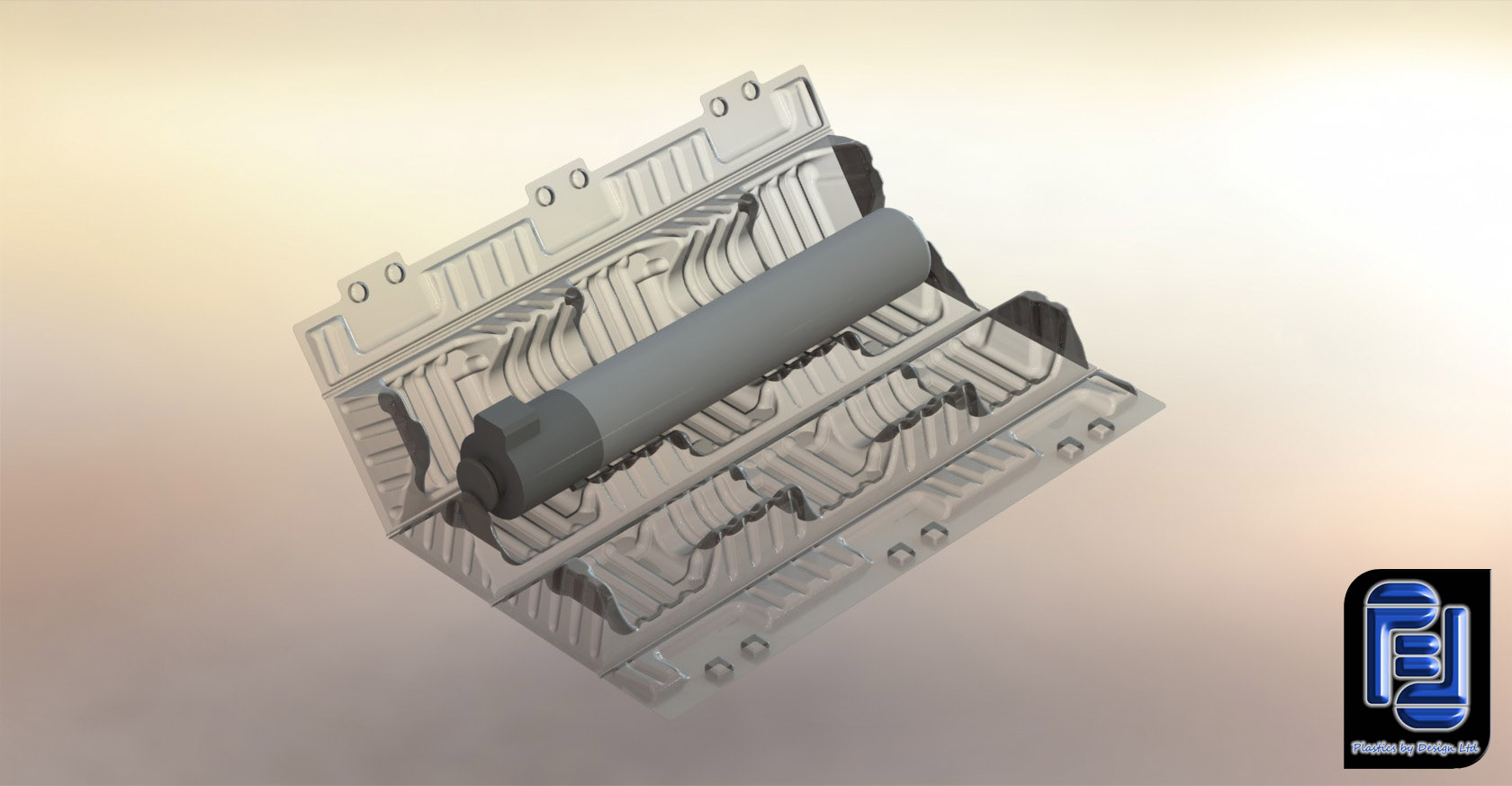

We do this by using crumple zones that allow for shock absorption alongside plastic thermoforming, a plastic manufacturing method that applies extreme force.

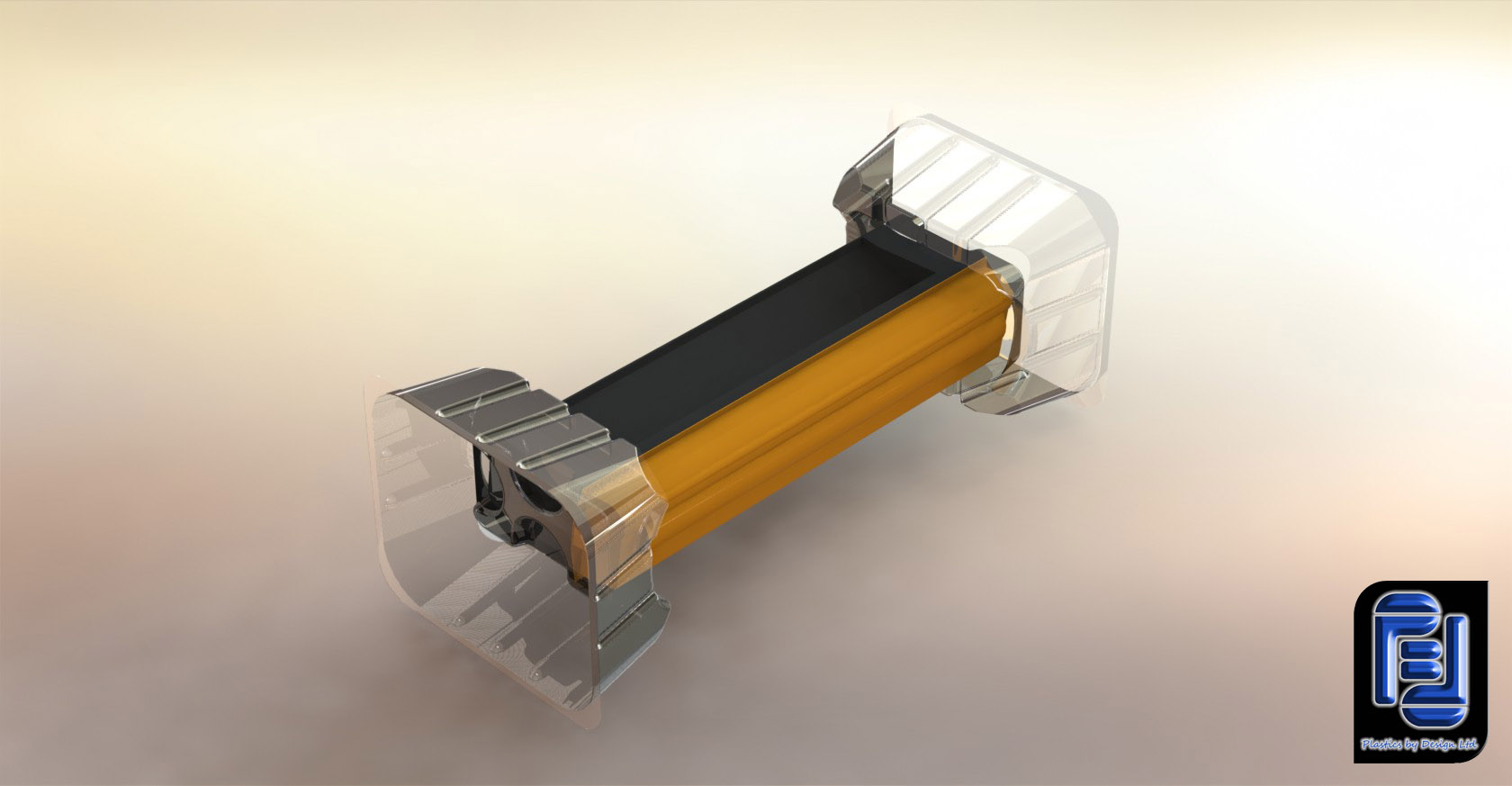

The heat stretches the plastic sheets to create 3-dimensional shapes that perfectly fit your shape item or product, making it immovable during transit.

We must check how your products hold up and whether or not they remain safe during all types of transit, and we do this using numerous methods and techniques that we have learnt over our many years of experience in the vacuum forming field.

Contact us today by calling the phone number on our website for a free quote if you are interested.

What are the advantages of vacuum forming?

Flexibility

Vaccum-formed packaging can be personalised to suit any of your products or any particular product shape. Plastic packaging can be custom-made by our professionals, no matter the shape or size.

We reject the idea of cookie-cutter packaging solutions as anything could happen to your items during the journey when they are put into a standard package.

Whatever your product requires or needs to keep it perfectly in place, we can provide. Many companies across the UK choose to use vacuum-formed packaging due to its extreme versatility; it is ideal for anything you are selling.

Meets Regulations

Food, drug products and industrial machines have numerous safety packaging vacuum regulations to comply with and adhere to to ensure they can sell them to customers on the market.

Whilst vacuum-formed packaging can be used for virtually any product as it is so versatile and high-quality, each package still must meet rigorous regulatory requirements.

Thus our experts design them to suit all varied industries and related products on the market.

More product, less packaging

Proper, compliant packaging suitable for all kinds of products is an exact process.

A single mistake or poor design choice that does not fit the product type could cost us hundreds and potentially thousands in unnecessary materials and result in overall waste, which isn't the best for us, the customers or the environment.

Vacuum-formed packaging has insurance against all potential costly mistakes and allows us to prevent these issues from occurring. Our vacuum-formed packaging can also be recycled easier than other forms of packaging.

Due to the careful packaging tailored to form around your particular product, there is often minimal opportunities for waste or mistakes along the way.

Our methods and techniques of packaging make vacuum-forming a fantastic, cost-effective choice for those searching for a way to deliver products without unnecessary, harmful extra plastic.

Brand recognition

Packaging is a considerable aspect that contributes to advertising and customer appeal.

Suppose you choose to spend significant amounts on print, online adverts and commercials or numerous other types of advertisements.

In that case, these are essential and wise choices that promote your product in practical ways.

However, if you also take time to solidify your brand by making your packaging stand out to be identifiable to your customers, you will likely achieve more sales.

Our vacuum-formed packaging allows you to create a unique shape and packaging for your product so that you can make a fantastic new impression amongst your competition.

Durability

In the modern world, companies can now ship their products and stock worldwide, over vast distances. Choosing a delicate material to package your product in it is a risky move as you could end up damaging it severely and lose out on mediums and money in the long run.

Through the transportation process or during shelving, your product could get badly damaged. The wear and tear on your units that end up on shelves could affect how customers view your product or items and potentially put them off a purchase.

Vaccum-formed plastic packaging is popular as it's incredibly durable during the journey; it maintains its initial shape when put through any extreme conditions.

Through harsh elements and man-handling, your product will stay protected within the vehicle and on shelves. Another great benefit of its durability is its ability to shelter your product and keep it in shape allows it to be more attractive to potential buyers and customers, therefore bringing in much more profit.

Key benefits of vacuum forming

Vacuum-formed packaging has numerous benefits and factors that allow it to stand out in the crowd and stay safe and intact during transportation.

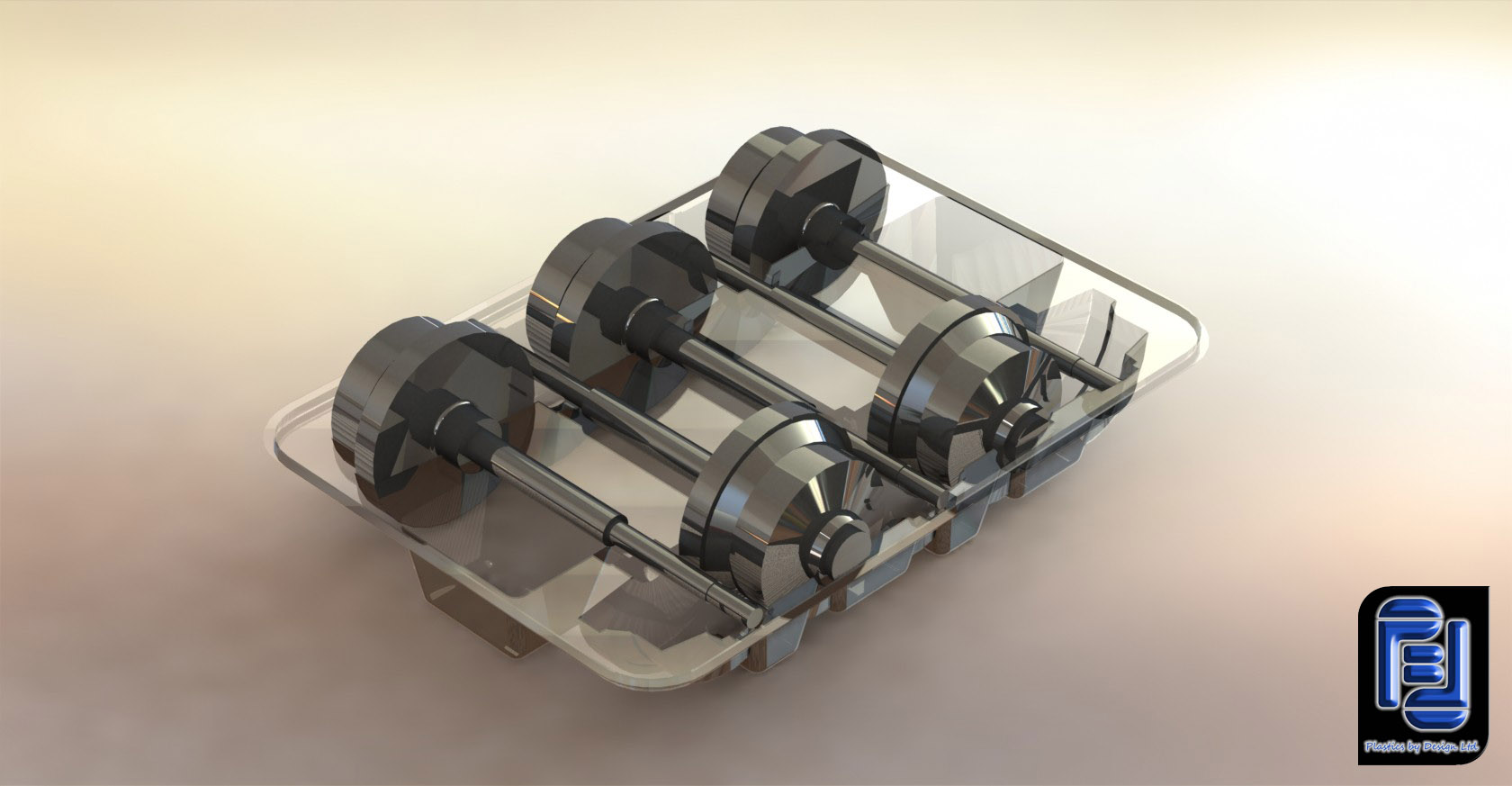

They are so ideal for all manufacturing industries to invest in when offering deliveries for products. Packaging inserts are specifically customised to provide all clients and customers with a precise fit.

The packaging form aids retrieval, handling and eliminates any potential movement or harsh movement in the container or box, reducing any severe damage.

Some of the key benefits to be aware of if you are interested are:

It is incredibly lightweight, perfect for ease of handling.

Minimises all movement and damages during transport journeys and handling

It allows your product to retain its shape and is rigidity when removed from the totes.

Our team can also layer it in totes and trays for additional efficiency.

It can be tailored to suit your components parts and overall product for optimum use and fit.

You may easily clean vacuum-formed packaging, and they are water, oil and grease resistant.

You can mould in instructions and parts numbers, etc. It can all be manufactured into custom sizes that suit you and your company or product requirements.

Its thin material or nesting allows saving space for when it is not in use.

ESD safe conductive versions are available for clients. It is incredibly ideal for all high-value or high volume items and their strict requirements.

Protective Packaging Manufacturers

Are you looking for Protective Packaging Manufacturers in the UK? We offer complete design and vacuum forming services to protect packaged goods.

At Plastics By Design Ltd, our business designs, develops and produces all our protective packaging with the highest standards, delivering the best quality packaging to our customers.

We have comprehensive customer service to target the best price, design, unique solutions, product loading and transportation for every client's project.

Our Process

With our expert team of designers, we know how to design and produce a plastic package that will enhance the stability of the product from being distorted, for example, using crumple zones that will allow for shock absorption.

The tests will enable us to check that your product will remain safe in the packaging through all types of transit. We can do this with various techniques that we have learnt through the 25 plus years of work we've done in vacuum forming.

Step One

We create designs that have come from the customer's spec/idea.

Step Two

We then make samples to show the customer so they can add their critique.

Engineering, prototyping and further developments all lead to the final step of production.

Step Three

We then produced the perfect package and delivered it to our customers in global reach.

Picking the proper protective packaging is crucial; this is important for the preservation, protection and transit of your products.

The most critical element to protect packaging is the safety of the product. Our protective packaging is highly specialised in using the best vehicle crash test machines.

We make sure every product is dropped tested to the legal specification and requirements. We do this to keep the item safe from any damage through transportation.

We have a vast product range to choose from, and if we don't already have the perfect forming, we design and sample for free!

A great advantage in plastic packaging compared to cardboard packaging is the assembling. Plastic packaging needs no assembling time or work.

It also can be various colours, textures and shapes, making the packaging more suitable to the actual product. You can also recycle the packaging when it arrives!

Get in touch with our protective packaging manufacturers today.