This article looks at the types of protective packaging and the advantages of each. Find out more about which protective packaging is right for you.

The use of protective packaging can be dated back as far as when material transport was necessary- including antique wooden boxes and clay pots.

Since then, they have evolved along with the development of technology, especially since the development of plastic technology a little over a century ago.

Types Of Protective Packaging

The versatile application of plastic meant that they quickly revolutionised the protective packaging industry.

Despite the recent media, there are many advantages to plastic protective packaging.

Plastics By Design Ltd are specialists in creating a bespoke protecting packaging solution for your products. Our experienced designers will assess your product and work closely with you to create a unique design for your product.

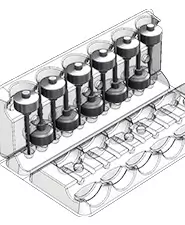

Box Inserts

Because of their plasticity, plastic can be moulded to any shape and design. Box inserts are commonly used in the packaging of retail items such as small parts.

Box inserts are also hugely beneficial to the environment as are lightweight and durable, cost less resources to make and transport and as with all of the products made by Plastics By Design Ltd, can be recycled to reclaim energy rather than going to landfill.

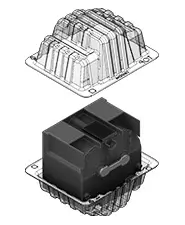

Clamshell Packaging

As the name suggests, these type of packaging is typically hinged on one side, resembling a clam when open.

They are widely used in multiple industries, from standard sized trays for baked goods to bespoke designs for a specific product.

Clamshell packaging offers a higher degree of protection to the product than blister packs. They are popular with the mechanical industry for transporting or retailing electrical and mechanical parts.

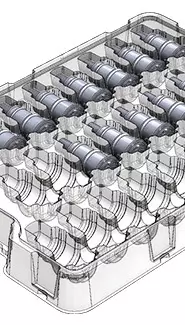

Transit Trays

Transit trays are commonly used to protect a product in while it's being transported, often used by the manufacturing industry. They are more durable than retail box inserts, or those containing baked goods.

Transit trays are almost always designed bespoke to fit the product and provide the maximum amount of protection to any fragile and delicate parts.

Unlike box inserts which are almost always disposed of by the consumer, transit trays have a high chance of being returned and reused by the recipient.

This contributes to maximising their efficiency and reducing the impact to the environment.

Why Use Protective Packaging?

The Unboxing Experience

Over the years, the unboxing experience has become a more dynamic ritual for consumers, especially those active on social media or influencers.

Now more than ever, people young and old are engaging in YouTube and TikTok content filled with prime consumers unboxing their goodies, whether freebies from brands and companies or their own exciting purchases.

Doing so creates a more personalised web experience, and it can link customers to your sites and products much faster.

In 2020 statistics reported that 40% of consumers took videos or pictures of their products during the unboxing stage, demonstrating just how important the quality of the packaging must be, no matter the company.

Many aren't willing to share a beaten or jagged box without padded dividers or air pillows on their social media unless they are doing so to raise a complaint, so bear this in mind.

Often this can be a fantastic way to boost social sharing and virality and, ultimately, is a secondary form of free, less targeted advertising on a grander scale.

Ensuring your product packaging is appealing and secure will help you gain traction within online communities. When your packaging can survive the rigours of transportation, delivery service of choice and warehousing, it is more likely to seem appealing to consumers across the board.

Superior Product Deliverance

When discussing product deliverance, what we mean is when one package arrives at a customer that has paid for a product, it allows for your product to announce itself without fear of being squashed or broken.

Aside from the store or the customer's initial look on its website, the package delivery is often the first genuine impression made on a consumer.

The appearance of a package resting on your doorstep is essential to your company's reputation. You must pass the initial stage of consumption in the eyes of your customers, as it is the first way to make them happy.

A product with battered or torn packaging will hardly earn you brownie points and could lose you a customer in the long run.

The best way to ensure your customers are happy and packaging demands are met is to optimise your packaging, ensuring that you align the product type or model with the correct/most suitable material to secure it and prevent movement. You can successfully increase the likelihood of curating a lifetime customer that could be back to purchase more.

Environmentally Friendly

In 2017, the trend of flexible, biodegradable packaging materials rose.

Due to the knowledge of our increasing climate crisis, consumers have emphasised their wishes to buy and invest in "green" products.

Such wishes for more environmentally friendly packaging have grown over the years, often as global warming grows more intense.

Consumers and companies made features like biodegradable materials and plant-based polymers a poignant focal point.

While we must all do more, consumers are becoming more eco-conscious than before.

Contact your local packaging professionals if you are searching for ways to involve yourself or your company in more eco-friendly practices.

They can help you navigate the materials; they're packaging formulas, and which ones would be best for your particular products.

Professionals in the industry are more likely to be familiar with the packaging applications that are more recyclable, sustainable and earth-friendly.

Many of these earth-friendly materials are bio-polymer, plant-based, biodegradable or bio-compostable.

Bio-plastic is becoming a more accessible alternative to traditional plastic in the packaging industry; it's popular with green and eco-friendly services with its Nurel or Nature Star plant-based substrates made of rice compounds.

Bio-poly based alternatives are also a fantastic and viable shrink film or stretch film substitute.

Several of these fragile items carry an incredibly high price tag; however, after significant technological advancements concerning their material formula, many wish to render their high cost and make them more accessible.

How to Choose the Best Protective Packaging Materials

Manufacturers and third party providers must aim to meet multiple protective packaging styles that meet the different needs of every existing product or commodity.

On the one hand, the product itself often deciphers which packaging material is most necessary for the journey, meaning the fragility of the product is highly considered for transportation.

However, on the other hand, the distribution cycles themselves are often considered so that sellers or manufacturers can decide which packaging would be most fitting for the journey or mode of transport.

or example, the packaging best suited for boat journeys will likely be different from that of a road, train or aeroplane due to the difference in motion.

The route of the journey could include harsh terrain, so manufacturers and sellers may want to make themselves aware of the physical impact of the journey when picking an ideal packaging material to ensure product safety.

Studying such products' variables and factors is entirely necessary, so many companies are dedicated to studying the best materials to utilise for product distribution across the UK, Europe, and worldwide.

Many of these companies have researchers that can assist you in selecting the most suitable product packing solutions that will optimise and validate the safety of your commodities and produce during their transport routes.

You can contact them and work together to efficiently reduce costs and damage to provide enhanced functionality and load stability.

Due to our current climate issues, many manufacturers are working on ways to make their packaging for deliveries and distributions more sustainable to be reused or contain materials that you can recycle.

What is Protector Packaging, and why do you need it?

Protective packaging often refers to various packages used to protect fragile items and safeguard materials from the threats they encounter during the distribution cycle.

Protective packaging and compartmentalised boxes provide a vast range of many protective materials, including corrugated boards, cardboard boxes and even more robust, complex materials like steel and sulfate pulp.

Depending on the goods that professionals in the industry must protect, protective packaging supply products can exist as a primary or secondary packaging priority.

Manufacturers design protective packaging options suitable for various types of goods.

Yet, the objective is virtually the same for each package, with the ultimate goal of guaranteeing the product's safety during transport, handling and storage as it reaches its destination.

The largest product protective packaging category can include these aspects for the same purpose, mainly utilised for three-dimensional structures:

- Foam-based products like packaging foam rolls, foam packing peanuts

- Egg crates

- Sponge Rolls

- Air pillows for a cushioning effect

- Bubble bags of multiple layers

- Butcher paper

- Padded divider sets or all-over padded surfaces

Should the product suffer any damage or potential harm during its travels, it can result in significant economic losses both on the seller and consumer's side. If this happens on more than one occasion, it could mean that the company gains a poor reputation and an overall bad image to potential consumers.

In the modern-day, one of the most popular and essential ways you can ensure that all packaged products arrive intact from one location to the next is to utilise high-quality protective packaging solutions.

Ensure you organise products into their categories to determine which material packaging options suit you best.

Through plenty of packaging research over the years, product study and transport simulation, it is entirely possible for us to determine the most suitable protective packaging materials perfect for every different product available. You'll want to invest in the packaging that tightly secures your items and merchandise.

Protect Your Property when moving and shipping supplies

When it comes to moving and shipping products and art supplies, protective packaging solutions are critical. Whilst the goal of all protective packaging is the same, there is no universal material that the masses and product spectrum can utilise.

There are often five different main types used to cover most of the online applications. However, the key is to use the correct protective packaging as it can ultimately mean the difference between a safe and intact shipment or a worn, destroyed one.

Plastics By Design Ltd care about the environment. Almost all of our plastic protective packaging is made from PET or RPET- both fully recyclable, with the latter being already recycled at least once.

If you would like more information on how we minimise our impact on the environment, please contact us via 01380 827 022 or use the form to forward your query.

Are you looking for Custom Thermoforming Services in the UK? To find out how Plastics By Design Ltd can provide you with better cost-effective solutions, Email: info@vacforming.uk.com or Call 01380 827 022 or follow the links below to find out more about our bespoke services.