Thermoforming Services

As industry leaders in precision moulding and shaping, we specialize in transforming thermoplastic materials into customized products of exceptional quality.

With state-of-the-art technology and unmatched expertise, we cater to diverse needs across various sectors.

Whether you require packaging solutions, automotive components, or medical devices, our thermoforming capabilities deliver innovation, efficiency, and reliability. Explore our range of services designed to meet your unique requirements and elevate your project to new heights.

Thermoforming Is Great For Large Plastic Projects

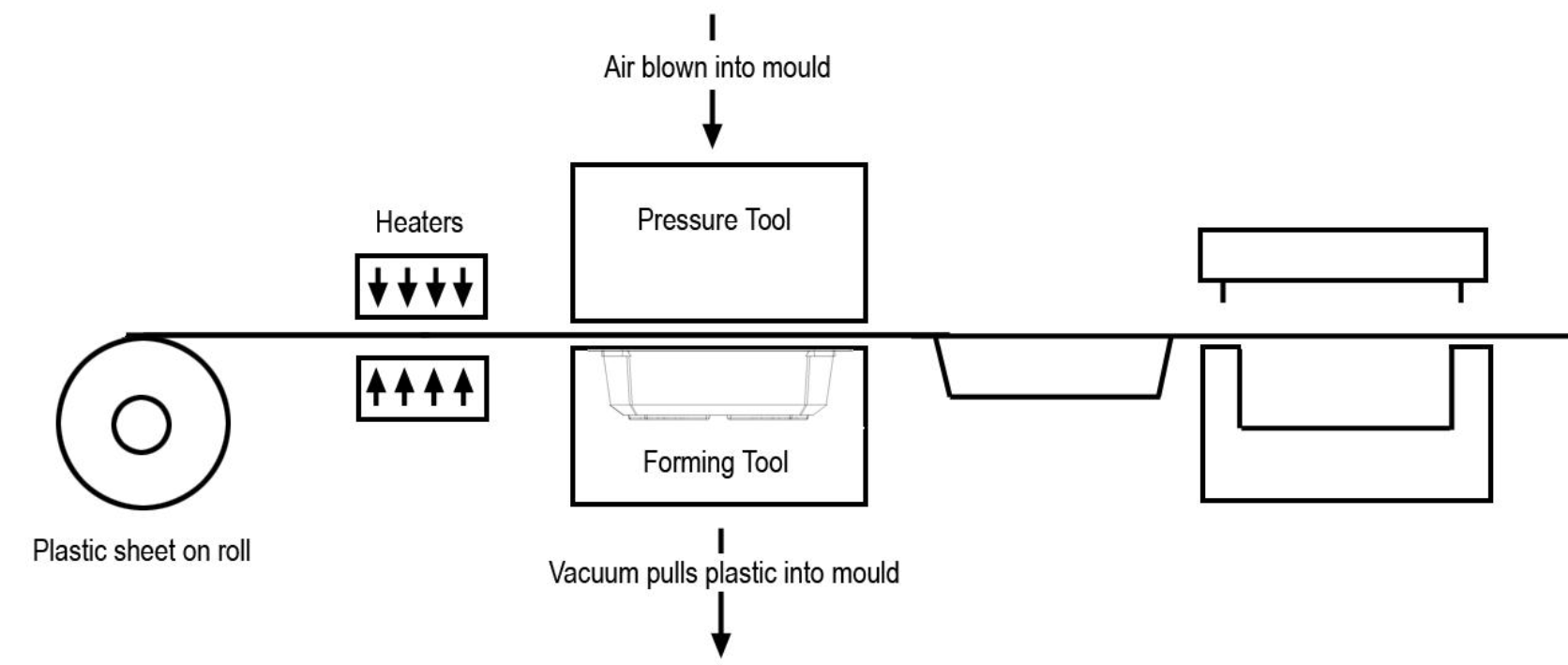

The process of thermoforming is particularly advantageous when it comes to handling large plastic projects. At its core, thermoforming involves heating a plastic sheet until it becomes pliable, after which it is formed over a male or female mould. When working with large-scale designs, this process excels due to its efficiency and the significant advantages it provides.

Unlike other plastic manufacturing methods such as injection moulding, thermoforming does not require heavy and complex machinery. This makes it an accessible choice for companies and craftsmen alike. Moreover, the process allows for any size of product to be created – even those that are exceptionally large. This is a significant benefit of thermoforming that sets it apart from other methods.

In addition, the process allows for a high level of detail in the final product, even when dealing with large-scale designs. The heated plastic sheets can be deftly shaped and formed to accommodate intricate details, resulting in the production of high-quality products that meet the exact requirements of the project. This underscores the flexibility and adaptability of thermoforming in handling large plastic projects.

Thermoforming Can Be Highly Sustainable

It is worth mentioning that recent strides have been made in developing more eco-friendly materials for thermoforming. As such, the use of bio-plastics, which are derived from renewable sources, and the incorporation of post-consumer recycled plastics into the manufacturing process helps reduce reliance on fossil fuels and minimises the generation of harmful greenhouse gases. In addition to requiring less energy in the production process, thermoforming generally reduces manufacturing costs and, in turn, product prices.

Affordability is a key attribute of thermoformed items, which means less financial burden on the end-user. Thus, by supporting thermoforming, consumers can not only buy cost-effective items but also contribute to environmental sustainability. Moreover, by choosing thermoforming, manufacturers are indirectly supporting the recycling industry.

Thermoforming encourages the use of recycled materials, and the recyclability of thermoformed products stimulates the market for recycled plastic. This is another significant way in which thermoforming contributes to sustainable development. Thermoforming also prevents excessive material usage. As it forms the products to their final shape right away, it eliminates the need for secondary operations like cutting and trimming, further aiding waste reduction. This aspect of material efficiency makes thermoforming a preferable choice to more wasteful production methods.

Lightweight and durable thermoformed products enjoy a longer lifespan, resulting in less frequent replacements that usually lead to increased waste. Long-lasting products also reduce expenditure for consumers, making them an economically viable choice in the longer term. The ecological implications of thermoforming make it an excellent option for our increasingly environmentally-conscious society.

By selecting thermoforming as a manufacturing method, businesses can reap both financial and environmental advantages, while consumers can benefit from the price affordability and the knowledge that they are aiding conservation efforts. The focus on sustainability and resource efficiency is not only trending but also necessary. And thermoforming supports this essential global movement towards more sustainable production practices. As we move forward into a more environmentally-conscious era, thermoforming stands out as a progressive solution amidst manufacturing strategies.

Thermoforming Is Highly Adaptable

Thermoforming is an extremely versatile manufacturing process favoured by diverse industries due to its numerous benefits. One of the primary advantages is its adaptability, which facilitates the production of a vast range of products. These can range from small items, such as packaging materials and trays, to larger components like vehicle parts and vast panels. Such versatility ensures that thermoforming remains an integral part of multiple industries.

The prowess of thermoforming lies within its capacity for customisation. This procedure allows for the creation of bespoke moulds tailored to match specific needs precisely, enabling the manufacture of individualised products that meet unique requirements. The capacity to offer such personalisation makes thermoforming an invaluable asset in product manufacturing. However, the versatility of thermoforming extends beyond just the design.

Material selection is another area where thermoforming shows its adaptability. The process provides the opportunity to choose from a broad range of plastics, all possessing various qualities and characteristics. This advantage ensures that the products created through thermoforming not only meet the design specifications but are also made with the most suitable materials to serve the intended purpose.

Overall, considering the spectrum of advantages from extensive adaptability in product design to a wide array of selectable materials, it's clear why thermoforming is an invaluable process in diverse industries and a key asset in product manufacturing. This process's ability to adapt to different requirements makes it a vital tool in modern manufacturing.

Low Costs And Fast Turnaround

Thermoforming is a cost-effective method of plastic production, particularly when compared to other processes, such as injection moulding. This technique utilises less expensive moulds, contributing to its cost-effectiveness. Further, it does not necessitate the use of intricate machinery. This feature greatly minimises the initial outlay and setup expenses, making it an appealing option for manufacturers seeking to minimise operative costs. Another key advantage of this method is the accelerated production times it offers. With thermoforming, designs can swiftly be brought to life. The process allows for the creation of detailed and optimised products in a shorter span of time.

Additionally, making modifications to the design is uncomplicated and straightforward. This can result in a more rapid turnaround time, delivering not only cost savings but also an efficient production timeline. These factors combined make thermoforming a powerful and reliable manufacturing technique. It provides significant advantages particularly in terms of cost and production efficiency, thus making it a strong choice for manufacturers.

These qualities underline its popularity in a variety of industries, realising the production of optimised, high-quality plastic goods at competitive prices. In the manufacturing landscape, achieving the right balance between quality, speed, and cost can be challenging. However, thermoforming effectively addresses these considerations, proving its worth for any manufacturing endeavour.

Thermoformed Products Are Built To Last

With the above-elucidated advantages, there is one noteworthy perk of thermoforming to discuss: the endurance of the products that it brings to life. The items created via thermoforming exhibit a high resistance to impact, making them exceptionally useful in a host of situations where durability sits high on the list of prerequisites. The vacuum or pressure-forming process, integral to thermoforming, welds a potent bond, resulting in products that can bravely endure everyday wear and tear, not to mention more formidable foes such as harsh environmental conditions.

What's more, there's the opportunity to select from a broad palette of materials to match the specific demands of the product. This ensures that items born from the thermoforming process are not only robust but also enjoy a long lifespan. Upon reflection, it is clear that the benefits of thermoforming are truly substantial. It offers flexibility and sustainability in its process — a contribution that is admirable in today's era of environmental consciousness. Further adding to its appeal, it also brings affordability to the table and produces durable products that guarantee value for money.

Thermoforming is an exemplary choice for a comprehensive range of manufacturing needs. It's a process that has already staked its claim across numerous sectors, and it's a sure bet that it will continue to play a pivotal role in the future. It's safe to say that thermoforming benefits are indispensable in ensuring a method of production that is both efficient and mindful, striking a crucial balance between productivity and responsibility.

In conclusion, thermoforming isn't merely an advantageous process — it's an innovative, versatile, and reliable approach to manufacturing. Its ability to create strong, durable products of varying sizes and shapes, whether for industrial use or for day-to-day consumer goods, is something to marvel at. Taking into account the reduced cost and speedy production times, thermoforming is an unquestionable champion in the manufacturing realm. No doubt, its significant benefits will ensure its continued ubiquity and essentiality in manufacturing for many years to come.

Are you looking for Pressure Forming or Vacuum Forming services in the UK? Follow the link below to find out more about our bespoke services.