Vacuum Forming is a common manufacturing process used throughout the world. But What is Vacuum Forming? We look at the Vacuum Forming process and the practical uses in industry.

Thermoforming Plastic Materials

Thermoforming, often known as vacuum forming, is one of the oldest and most widely used methods of processing plastic materials. Items created by vacuuming may be found all around us and play a vital part in our daily lives. Softening a plastic sheet and stretching it over a mould is the method.

To draw the sheet into the mould, a vacuum is employed. The sheet is then removed from the mould. In its advanced form, the vacuum forming process incorporates complicated pneumatic, hydraulic, and temperature controls, allowing for higher production rates and more intricate vacuum formed products.

Plastic vacuum forming is substantially more expensive than injection moulding. As a result, vacuum forming is better suited for low to medium volume requirements where the necessity for and hence the expense of an operator or technician making each forming does not counteract the initial cheap cost of the vacuum forming tool.

PMMA Vacuum Forming PMMA (polymethyl methacrylate) is a clear thermoplastic often known as acrylic glass or acrylic. Since it's hard, light and shatterproof, it is frequently used and fitted as a substitute for glass.

High impact polystyrene (HIPS) is a robust, stiff plastic with great impact strength. It's simple to cut, trim, and machine, and it comes in a number of colours. As a result, this low-cost plastic is beneficial in the production of toys, signage, and point-of-sale displays.

Polycarbonate is a tough, long-lasting polymer with excellent impact strength. While it is one of the most costly polymers, it is self-extinguishing and has several applications in the aerospace sector, including visors, riot shields, and machine guards.

Vacuum shaping is often used on the interior and outside of all sorts of automobiles. It may be used to create pieces that are light enough for airplanes yet sturdy enough for agricultural machinery, buses, boats and HGVs.

Due to its great impact resistance, while being flexible, high-density polyethylene (HDPE) is mostly utilised for caravan and automobile parts. It is simple to construct and weld, and it is one of the less expensive polymers used in vacuum forming.

The most basic technique of polyvinyl chloride thermoforming is vacuum forming, in which the PVC is heated to a pliable condition before being fitted to a bespoke tool.

Plastic must be handled with caution. If not, it may distort or bubble. To some extent, there may be ways to recover from this. Damaged or extra plastic, for example, may frequently be reused in future manufacture.

The Pros and Cons of Vacuum Forming

When compared to other manufacturing techniques, vacuum forming is preferred by many manufacturers, designers, and other professionals because it combines design freedom with a cheap cost. Vacuum forming is becoming more popular as an alternative to glass.

So far, it has mostly been employed in small-scale applications such as skylights and light diffusers. This might perhaps be extended in the future. Some of the benefits of vacuum forming are as follows:

Affordability

Vacuum forming is often less expensive than other manufacturing processes, such as plastic injection moulding, for lower production runs (250-300 units per year).

The decreased cost of tooling and prototyping contributes significantly to the affordability of vacuum forming. Tooling for injection moulding can cost two to three times as much as tools for plastic thermoforming or vacuum forming, depending on the surface area of the pieces being created and the size of the clamp frame.

Turnaround Time

Since tooling can be manufactured more quickly, vacuum forming has a faster turnaround time than other traditional production processes. The time necessary to make vacuum forming tooling is approximately half that required to produce injection moulding tooling.

Turnaround time may be reduced even more when 3D printers are utilised to make moulds. Vacuum forming allows firms to get innovative ideas into the hands of customers faster by boosting the efficiency of the manufacturing process.

Flexibility

Vacuum forming allows designers and manufacturers to test new concepts and prototypes without incurring large expenses or lag times.

Moulds can be formed of wood, metal, structural foam, or 3D printed polymers, making them more readily swapped out and/or modified than conventional production procedures.

Dick Teal used vacuum forming to test prototype John Deere snowmobile components in the late 1970s and early 1980s, mostly to decrease tooling costs. Vacuum forming also allows designers to provide clients with greater colour selections and customisation. This allows many firms to offer one-of-a-kind designs and personalised items, like dental retainers, to clients at a reasonable price.

The Vacuum Forming Process:

Clamping

The clamp construction must be robust enough to keep the plastic sheet securely in place during the forming process. It can handle the thickest material that the machine is expected to generate - up to 6mm for single heater machines and up to 10mm for dual heater machines.

To prevent accidental damage, the action of the moving parts must be guarded and interlocked if an automated approach is utilised. A safety guard must also be present at all times to safeguard the machine operator.

Heating

Infrared components are often installed within an aluminium reflector plate to form heaters. To get the optimum vacuum forming results with any material, the sheet must be heated consistently throughout its whole surface area and thickness.

To do this, a system of zones that is regulated by energy regulators is required. Ceramics do have a drawback in that their large thermal mass causes them to warm up slowly (about 15 minutes) and to respond slowly when modifications are made.

The mould will be raised upwards towards the plastic after it has reached the proper temperature. The vacuum pump will then be activated.

This will remove all of the air from the machine. The plastic will be pulled to the instrument as it does so. This operation must be completed rapidly so that the plastic remains heated and bendable.

There are more advanced quartz heaters available with less thermal mass and a faster reaction time. By monitoring the melting temperature of the sheet and engaging with the operational process control, pyrometers offer precise heat temperature management.

A computer-controlled system that works in tandem with the pyrometers can also provide precise temperature readings. When forming heavier materials, twin heaters are also suggested since they help to provide more consistent heat penetration and quicker cycle times.

Twin quartz heaters are ideal when forming high-temperature materials with critical forming temperatures. Heat losses at the margins caused by convection air currents and absorption from clamp regions may be fully compensated for and consistent results obtained continuously by strictly managing heat intensity areas.

While quartz heaters are used, an adjustable percentage power drop occurs when the heaters are in the rear position during the forming process, which can result in considerable cost savings.

Sheet Level

The machine has a photoelectric beam that scans between the bottom heater and the plastic sheet. If the plastic sheet sags and breaks the beam, a little amount of air is introduced into the bottom chamber, elevating the sheet and preventing it from drooping.

To avoid webbing, you must manage how the plastic extends or is drawn inward into the mould so that it never expands too far anyplace and can shrink enough to meet the form without folding up.

Pre-Stretch

Once the plastic has attained its "plastic" condition, it can be pre-stretched to guarantee equal wall thickness when the vacuum is applied.

The approach for adjusting bubble height should produce consistent results. The heated, stretched plastic is subsequently moulded using vacuum, air pressure, and optional aids such as a plug assist.

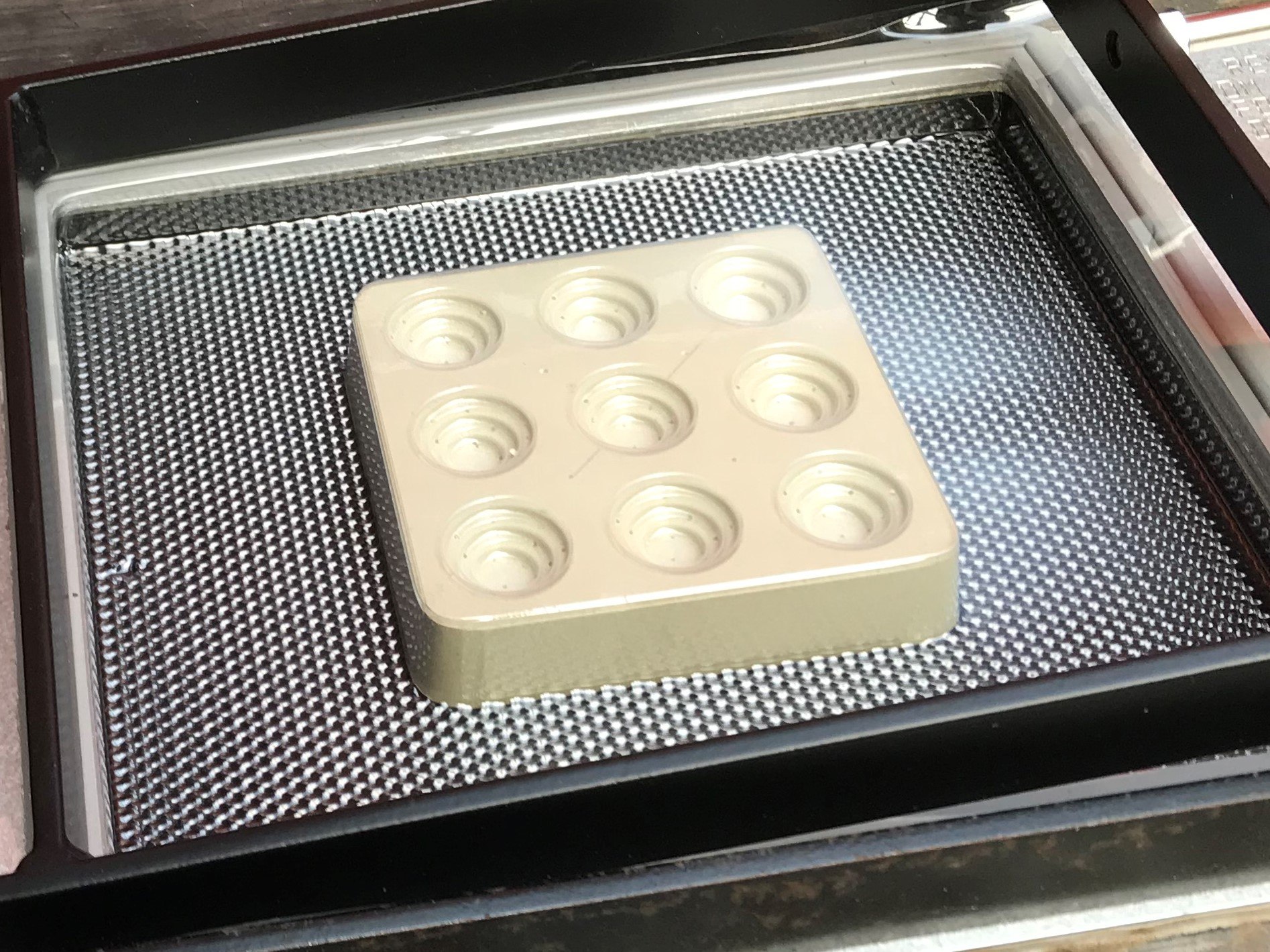

Plug Assist

When it is difficult to distribute the thermoplastic sheet evenly to all sections of the mould using straight vacuum forming, plug assisted vacuum forming (moulding) is used.

A plug is used to push the sheet into the mould before applying the suction to help spread it out more evenly. This process permits additional thermoplastic material to reach the bottom of the mould, giving extra material to fill the mould's corners and prevent the plastic from thinning out.

Vacuum

Once the material has been sufficiently pre-stretched, a vacuum can be used to aid in the production of the sheet. To remove the trapped air between the sheet and the mould, a dry vane vacuum pump is employed. A pressure difference of around 27" mercury should be maintained by the vacuum pump.

A vacuum reservoir is utilised in combination with a high volume capacity vacuum pump in bigger equipment. This allows for the employment of a two-stage vacuum, resulting in the heated sheet being shaped quickly (before the sheet temperature drops below its ideal forming temperature).

Cooling and Release

After being made, the plastic must cool before it can be released. If the component is removed too soon, the moulding will distort, resulting in a rejected part.

Fans are installed and switched on after the component is created to speed up the cooling process. A spray mist alternative is also available, which involves attaching nozzles to the fans and spraying a tiny mist of cold water over the sheet.

In conjunction with the fans, this can accelerate the cooling cycle by up to 30%. Mould temperature control systems are also available for chilling crystalline and crystallising polymers such as PP, HDPE, and PET to provide precise and consistent cooling times.

Trimming and Finishing

Excess material is removed once the produced component has cooled and been taken from the machine. The component is then drilled with holes, slots, and cut-outs.

Decoration, printing, strengthening, reinforcing, and assembling are examples of post-forming operations. To cut the product off the sheet, a number of trimming processes are utilised.

The ideal equipment for the job is determined by the kind of cut, the size of the item, the draw ratio, the thickness of the material, and the output quantity required. Mechanical trim presses also called roller presses, are commonly used to trim thin gauge items.

Typical Applications

Heavy gauge vacuum formed components are used by original equipment manufacturers (OEMs) to produce between 250 and 3000 units per year.

Vacuum-formed components can replace intricately made sheet metal, fibreglass, or plastic injection moulding.

Outdoor kiosks and automated teller machines are typical industrial examples, as are enclosures for medical imaging and diagnostic equipment, engine covers in a truck cab or for construction equipment, and train interior trim and seat components.

Hobbyists frequently utilise vacuum formers to create masks and remote control cars.

Types of Moulds

Vacuum forming may be used to create a variety of designs. Take any little thing, reproduce it many times, and then vacuum shape the new pattern to make a more coherent form.

The vacuum forming helps to connect the separate elements and create one mould out of several pieces that can be readily repeated. Plaster, concrete, and other materials can then be cast into the plastic shape. Wood patterns are a popular material for vacuum forming since they are very affordable and allow the client to simply adjust the design.

The number of samples obtained from any pattern is determined by the size of the portion and the thickness of the material. Once the part's parameters are completed, the pattern is utilised to make a ceramic composite mould or a cast aluminium mould for regular manufacturing.

Temperature control lines are often routed via cast aluminium moulds created in a foundry. This aids in the regulation of the temperature of the plastic being made and speeds up the manufacturing process. Aluminium moulds can be male or female and used in pressure forming. The most significant downside of this form of mould is its high cost.

Machined aluminium moulds are similar to cast aluminium moulds in that they are machined from a solid block of aluminium utilising a CNC machine and a CAD application. Machined aluminium is typically utilised for shallow draw pieces made of thin gauge material.

Packaging and trays are examples of possible applications. With this form of tooling, the cost is a major consideration.

Positive convex moulds (male moulds) indicate that the plastic was manufactured over them. As a result, positive moulds favour interior component dimensions. There are also concave negative moulds (female moulds); this implies that plastic is produced within them.

As a result, negative moulds prioritise the exterior dimensions of the component. Regardless of the sort of mould used, it must be made in such a manner that the plastic may be released without being damaged. Composite moulds are less expensive than cast or machined aluminium moulds.

Composite moulds are often formed of filled resins that begin as liquids and solidify over time. Composite moulds may endure a long period and create high-quality parts, depending on the application.

Are you looking for Pressure Forming or Vacuum Forming services in the UK? Follow the link below to find out more about our bespoke services.