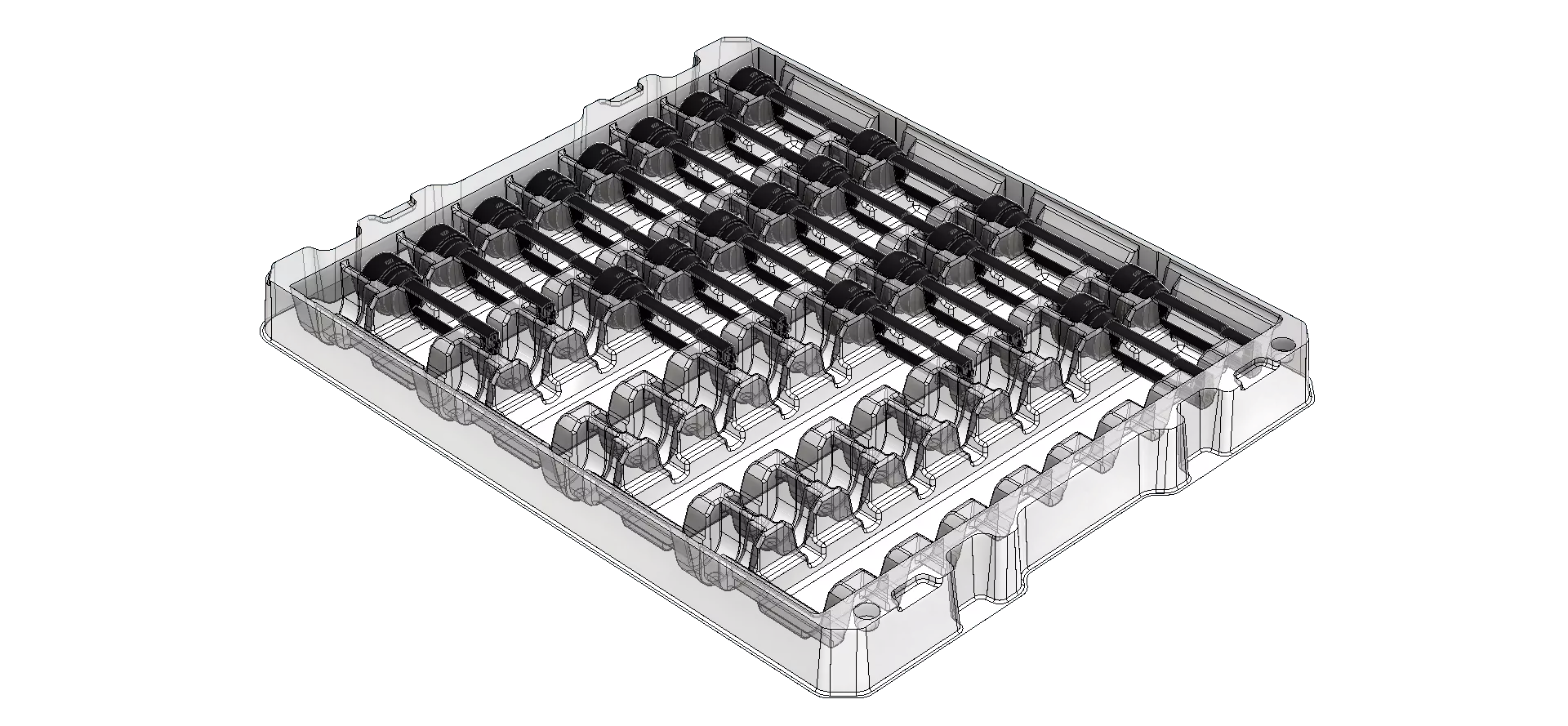

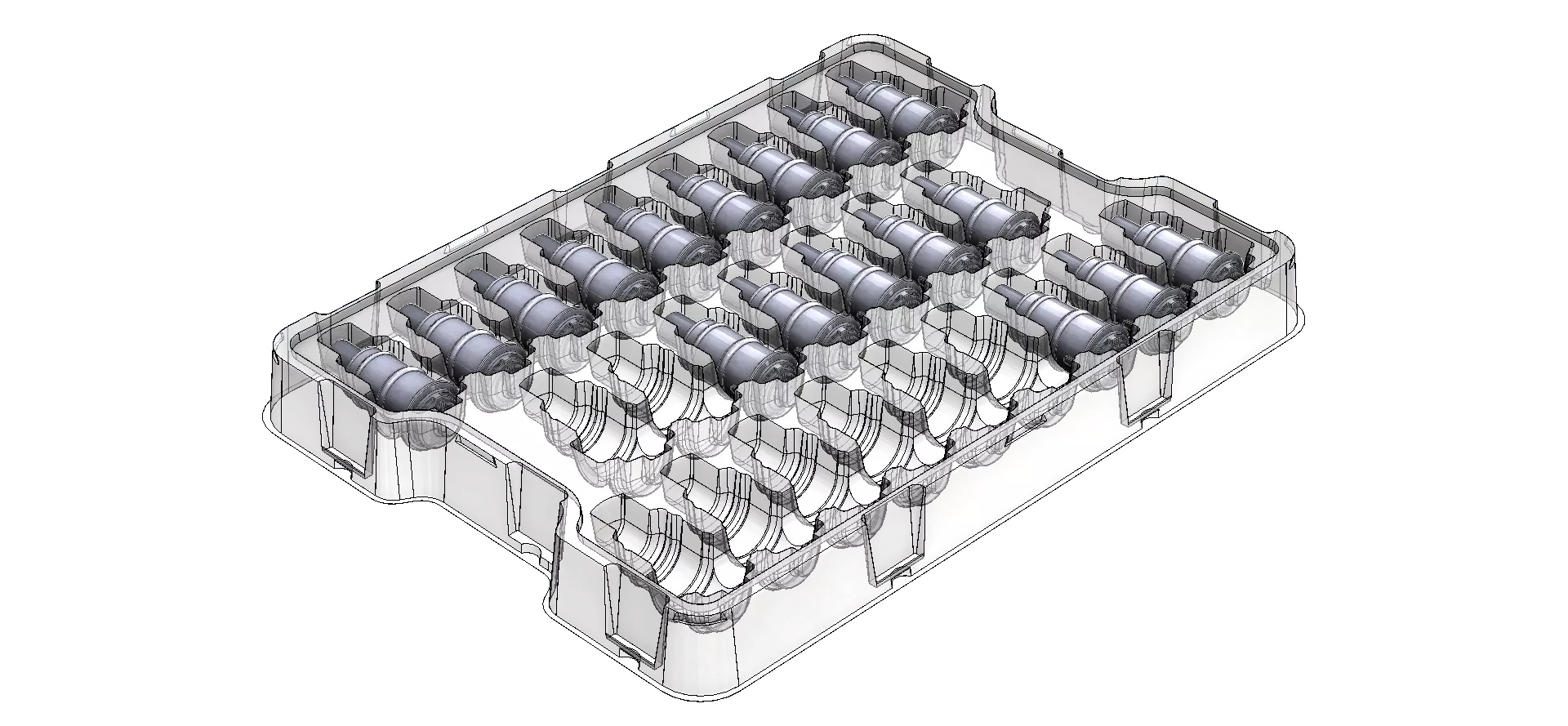

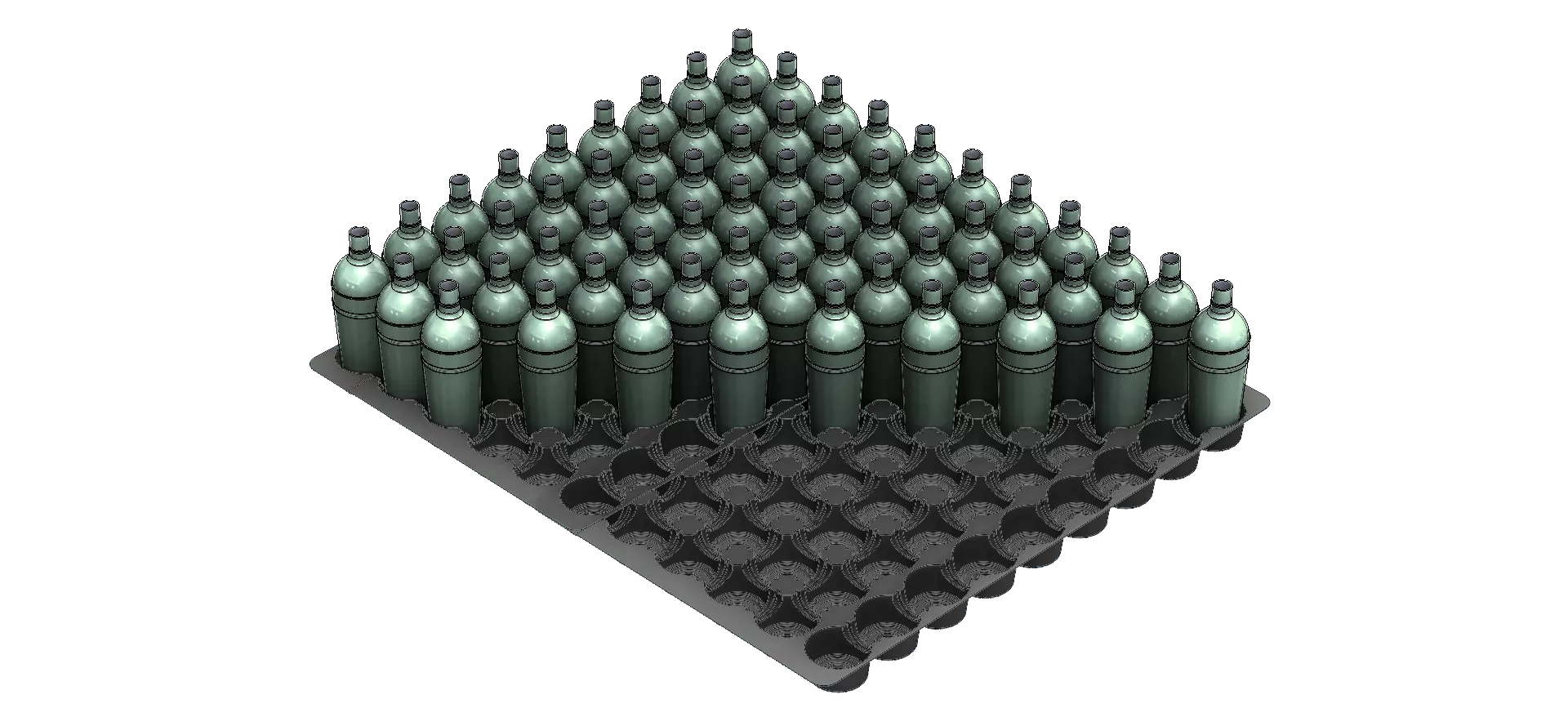

Vacuum Formed Transit Trays or Component Trays

Considering that transit trays are essential packaging components for shielding your products or elements from damage, you will want them to be trustworthy, eco-friendly, able to increase cost, maintain your company's reputation and also improve performance and efficiency.

Vacuum formed transit trays are created and manufactured to offer maximum security to an unpacked item, avoid any damages or breakages and also keep them clean and free from dust, dampness and chemicals. They are commonly used for automotive/electronic elements, but are useful for many other items.

Plastics By Design Ltd possesses an extensive history in the thermoforming industry.

We have completed a comprehensive range of projects for our clients throughout the years, gaining experience and expert knowledge.

This means we can give our clients the best service and advice possible to suit their needs, down to the ground.

Our bespoke trays and totes meet the storage, handling and also circulation demands of a wide variety of markets. These industries include general industrial, automotive, food and beverages, horticulture, pharmaceutical and many more!

How Vacuum Forming Works

The primary process for vacuum forming involves specialist equipment and tools. Below is a rough guide which explains how to create the vacuum formed trays:

- A thermoplastic sheet is placed in a clamp, to hold it steadily in place

- The plastic sheet is heated up to form a template

- This sheet is attached to a mould in the shape of the transit tray you wish you make

- Once the mould and sheet have been prepared, the vacuum is activated

- The vacuum causes pressure against the sheet and the mould

- Now, the shape of the tray is moulded and left to cool down

- When the finishing product is cooled down, the mould is removed, leaving the plastic transit tray behind

- Colours are then added to the tray, and it is specifically designed to match the customer's requirements

- The vacuum formed tray is then tidied up, cut down to size, and ready to be sold

Key Benefits

Vacuum formed transit trays provide several advantages over conventional packaging, such as foam inserts.

No assembly required, no fibre contamination, as well as the capability for re-use and recycling, making them economical and environmentally friendly.

Additionally, the trays can be made to stack for space-efficient storage.The main key benefits of vacuum formed transit trays are:

- Single or Multi-use

- Produced to be stackable throughout usage or nestable for storage area

- Resistant to water, oil and chemicals

- Light-weight and also self-stacking

- Reduces the movement of the product whilst in transit

- Versatile - (i.e. safety, or beneficial just as logistical help)

- Cost effective

- Easy to Clean

- Customisable

- Fit exactly to the shape of the product

- Reduces customer returns

- Improve productivity and efficiency within a business

Uses and Application

There are a wide variety of uses for vacuum formed transit trays, and they can be very beneficial for a lot of different companies and industries.

Several of the products that we have provided plastic transit trays for include:

- Medicines and Other Pharmaceutical Items

- Cosmetics

- Automotive parts

- Medical Parts

- CNC machined components

- Electrical Components

- Glass bottles

- Pre-packaged Products

- Retail Product packaging

- Consumer Packaging

- Clean Room Application

- Company Customisation

The density of products differs from 500 microns for lightweight items, and as much as 6mm ABS for sturdy applications.

Oil, anti-static and detergent-resistant materials can be used in applications where the transit trays should be cleaned and sanitised after use, such as liquids or cosmetics.

How do Transit Trays or Component Trays Improve Productivity?

If you are keen to improve the productivity in your business, making it more efficient, lowering costs and speeding up the process, then you need vacuum formed transit trays!

These products are sold at extremely affordable prices, reducing the expenses your company pays out and increasing the amount of trays you'll be able to buy. This further increases the number of products you'll be able to ship out, as you'll have more equipment to do so.

Safety and handling are improved, as they are light in weight, and so is the packaging they come in. They have been specifically designed to cut your workload in half, by being stackable.

This means you can stack the trays on top of each other, cutting down the number of trips back and forth you need to take.

They take up a minimal amount of storage space, and they have many useful features to improve the efficiency of your company. They have different compartments to be able to store any information you require about the products and any other accessories that may be needed.

Part Protection

Protection of products during transit is so important, as it can have a financial impact on your business. This is caused by wasting stock due to damage, breakages and refunds for customers returning the products. These vacuum formed trays are moulded to fit the exact shape of the product you are sending, improving the control of movement during transit.

This will ensure high-quality standards of your products and continuous business as people will want to buy from you again. Having a high number of customer returns and complaints can ruin the reputation of your business, which is why it is so important to have the necessary equipment.

Due to the material and manufacturing of these trays, they are resistant to water and chemicals. They are extremely tough and thick, and are also very easy to clean, as they won't gather dust. These trays can be recycled and reused, which is also important for the economy and environment.

Custom Options

Vacuum formed transit trays can be customised for a number of different useful reasons, and a variety of ways the trays can be customised, to help prove the efficiency within your production line.

Colour and Design:

If your company has specific colours or has a logo, then these can be printed on the trays for brand recognition. Different colours are also useful to determine which products are which, or which section they are from, which reduces time spent having to try and find out.

ESD Safe Material:

To improve the safety of the transit of electronics, or easily breakable items, this material is anti-static and can be used to make the trays. This also decreases the chance of damage during the handling of the product.

Stackable:

Making the trays stackable will help reduce the amount of storage space required, as they will easily be able to fit on top of each other. This will also mean you can have more than one product sent in one go as the stacking lugs will just slide together and improve productivity.

Are you looking for Custom Thermoforming Services in the UK? To find out how Plastics By Design Ltd can provide you with better cost-effective solutions, Email: info@vacforming.uk.com or Call 01380 827 022 or follow the links below to find out more about our bespoke services.